This machine is essential for precise and efficient concrete strength testing, ensuring compliance with industry standards critical to civil construction.

It is widely used in construction projects and laboratories to validate the quality and durability of concrete materials.

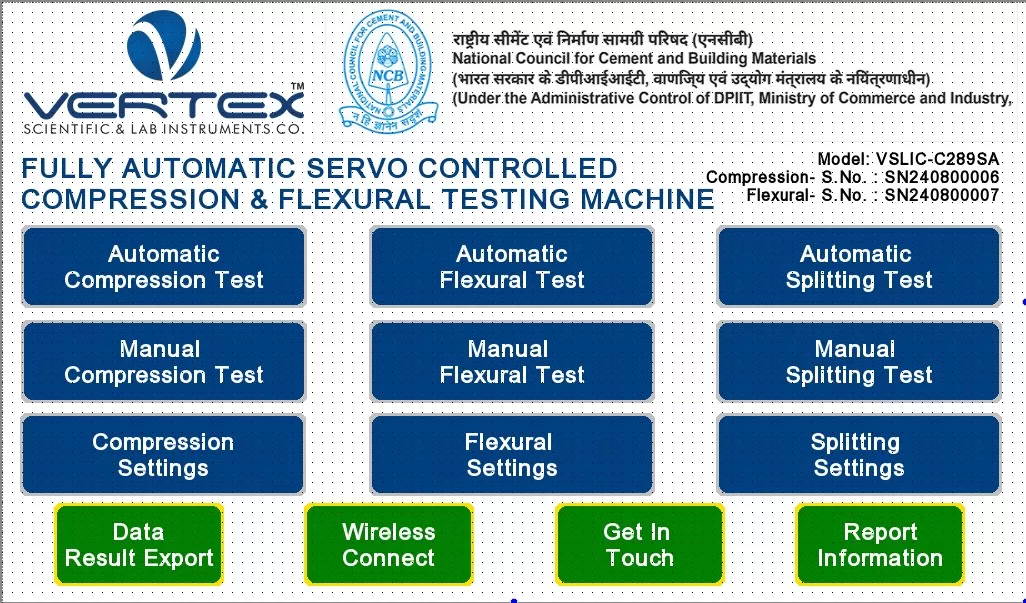

Automatic Operation: Minimal user input required; automatic rapid piston approach, test speed adjustment, and motor stop after specimen failure.

Adjustable Automatic pace rate (0.01 kN/sec to 20 kN/sec) with dual-stage pump for fast and precise execution.

Robust Frame: High-stiffness welded frame with a heavy-duty spherical seat for accurate specimen alignment.PC software for two-way communication, result storage, and report printing.

Automatic Test Execution

Once the machine has been switched on, the specimen positioned and centered, the only required operations are:

Set test parameters including load rate

- Press the start button

- Tighten the pressure valve

- The machine automatically: starts the rapid approach; switches to the test speed once the specimen comes into contact with the upper platen; automatically stops the motor upon specimen failure

- Save the test including data results .

- The test execution conforming to Standards can be easily proved.

- Working on 240V, 50 60Hz, single phase.

- Dual stage pump assuring fast piston approach and precise test execution

- Test execution conforming to EN 12390 4, ASTM C39, AASHTO T22

- Controllable pace rate from 0.01 KN/Sec to 20 KN/Sec.

- Auto stop after completion of each test.

- Soft platen to specimen contact and smooth load rate control from the very beginning of the ramp

- Servo motor driven machine

Frame

- Four column high stiffness welded frame tested for stability.

- Heavy duty spherical seat, allowing initial free alignment at the initial contact with the specimen and automatic jamming up to the end of test.

- Surface hardness of platen is 55 HRC, flatness tolerance 0.03 mm. Traceable certificate of surface hardness available on request.

- Piston travel limit switch (Extra cost)

- Emergency stop button

- Servo motor driven machine

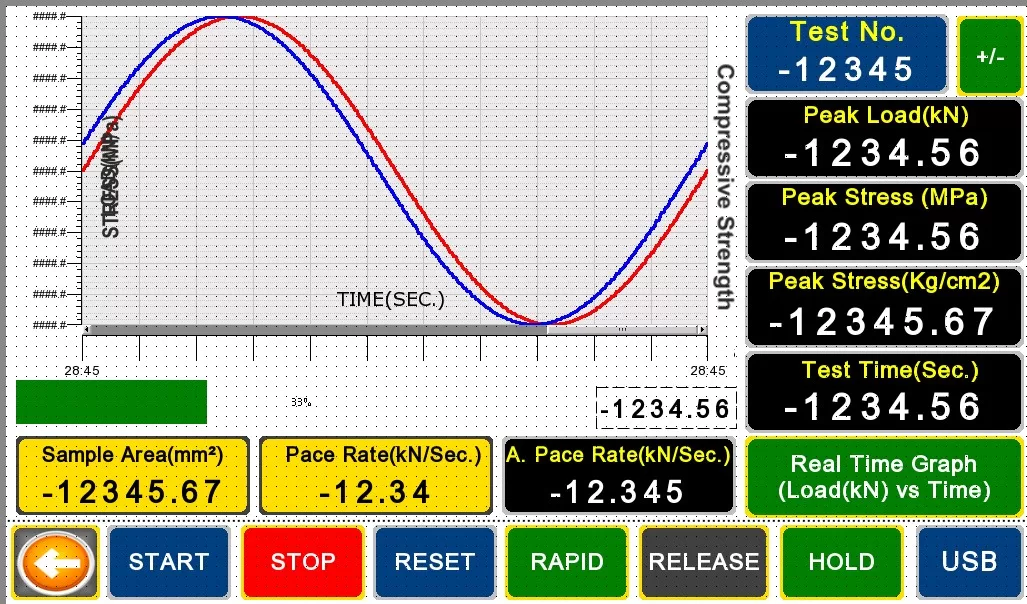

- Gives live online graph on the 7″ touch screen

- User friendly large graphical display

- Displacement controlled machine also available (at extra cost)

- Saves 100 results in the 7″ touch screen

- Inbuilt USB drive to save the data.

Salient features of data manager PC software (Optional At Extra Cost.)

- Two way communication i.e machine operates from computer and from the touch screen controller both (Stat, stop, save data and save graph)

- Results directly saved in excel file.

- Graph also saved in excel file.

- Capable to save customer name, other details of customer, ageing of cube molds, identification mark of the cube mold, date and time of testing

- Capable to print direct report from the computer.

- Capable to select different test parameters like pace rate, sample size and area from the computer (software)

- Capable to select different type of tests, like flexural, CTM, aggregate crushing etc.

NOTE : It is recommended to use the machine with 3 KVA servo stabilizer