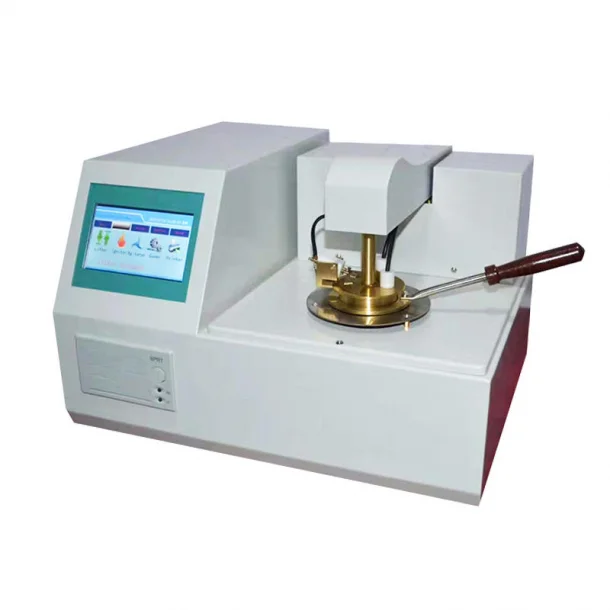

The Cleveland flash point apparatus is a top-of-the-line flash point instrument designed to deliver accurate and reliable results for determining the flash point of various substances. This advanced flash point machine is essential for laboratories, quality control departments, and research facilities, ensuring precise measurement and compliance with safety standards.

Compliance Standards:

ASTM D92, ISO 2592, IS : 1448, IP 36

Salient Features:

- Standalone model with touch screen display.

- Accurate determination of Flash Point

- Easy operation: Select procedure, enter Expected Flash Point and click on start. Instrument follows the exact procedure and completion of the test cycle is signaled by beeps, with on-screen message of test completion. Results will be stored at the end of the experiment.

- Rapid heating procedure for high flash point till selected temperature below expected flash point

- Search programs enable a quick determination of fully unknown samples

- Interchangeable gas or electric igniter source

- Automatic barometric pressure correction

- Interlocks for safe operation

- Stores more than 500 test/results

- Capable to save user defined methods / procedures

Calibration

- Sample temperature sensor calibration

- Barometric pressure sensor calibration

User Interface:

- Windows based user friendly Software

- In-built method and results storage

- Standalone with inbuilt PC having 8.4” touch screen display

- With LIMS compatibility RS 232, LAN , Wi-Fi, Bluetooth and USB Ports for Printer & other peripherals.

Heating:

- Coil type heater, 450 watt @ 230VAC

- Heat rate as per method or defined by the user from 1 to 20°C/min

Cooling : Centrifugal Blower 56.5 CFM, 35 watt @ 230VAC

Stirring : Stepper Motor controlled movement with 3-steps electric igniter & brightness adjustment

Ignition:

- Stepper motor controlled movement

- 3 step Electric Igniter brightness adjustment

Arm Movement:

- Automatic DC motor controlled swing arm

- Permanently fixed Cup, sample temperature sensor, Flash detector, Fire detector and Igniter for easy operation

Flame Extinguisher:

Automatically extinguishes the flame covering the cup, in case fire is detected or after fire, flash point is detected

Measurements:

- Auto-Cal : Prior to Every run, auto temperature calibration will be performed without the use of any calibration device.

- Sample Temp : PT-100 Class A, SS sheath, Range 0 to 400°C

- Bath Temp : PT-100 Class A, Disk Type, Range 0 to 500°C

- Flash Detection : Ionization ring.

- Amb. Pressure : Built in pressure sensor, Range 700 to 1100 hpa (500 to 800 mmHg)

- Fire detection : Thermal Sensor

Safety interlocks:

- Temperature sensors (bath/sample) is found defective.

- Flash Detector is found defective.

- Electric Igniter is blown off.

- Test Stop at above expected FP as selected or at 400 °C

- Upon Detection of Fire , warning buzzer will beep and power will cut off.

- Arm is not set in place.

Operating requirements:

- Power Supply : 230 Volts, 50 Hz, 1500 watt

- Housing : (W410 x D420 x H330) mm

- Weight : 16 Kg

- Ambient Temp : 10 to 35 °C

- Relative Humidity : 80% at 35 °C