For determining the hardness number of mastic asphalt for flooring.

It consists of an internally insulated cabinet to the base of which is fitted a water bath having two taps. The bath is heated by an immersion heater and the temperature is controlled with a thermostat at 350+/- 0.50C. A 6.35 mm dia pin is loaded on the specimen by means of a lever to give 31.7 kg. Weight. A dial gauge 0.01 mm x 25 mm is provided to record the penetration of pin into the specimen.

Application and principle:

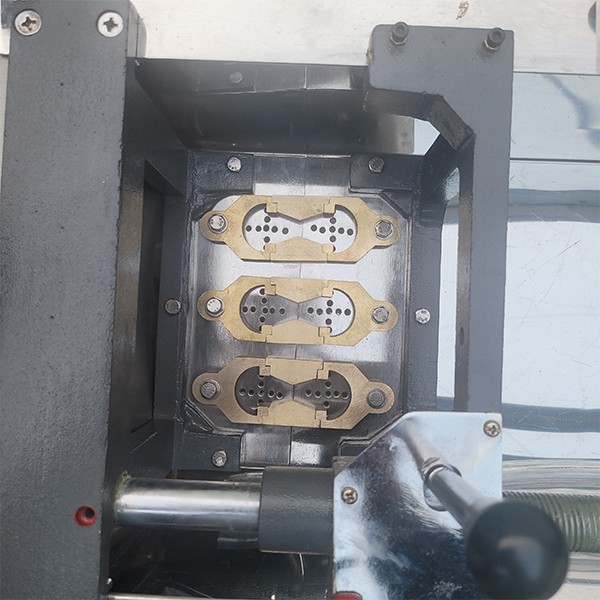

Ductility is defined as distance in cms to which a standard briquette of bitumen can be stretched before the thread breaks. The briquette is stretched at a rate of 50 mm/min. ± 2.5mm per minute at a temperature of 25°C ± 0.1°C

Apparatus Description:

The apparatus consists of water bath with a thermostatic heater, and a circulating pump to maintain uniform water temperature. One half of the briquette moulds is fixed in a fixed plate in the water bath, the other half of the briquette mould is fixed to a carrier, which slides over a rotating threaded shaft with a clutch. The motor and gears to rotate the shaft are housed in a cabinet fixed above the other end of the bath. A pointer fixed to the carrier moves over a scale graduated from 0‑100 cm x 1mm fixed on the bath with “0” (Zero) of the scale towards the fixed plates side. The rotating shaft has 2 speeds of travel for the bracket, 5 cm/min and 1 cm/min ‑ selected by a clutch. Water bath inside is of stainless steel with insulation and water drain cock . A heater with thermostatic control is fitted inside the water bath. Control switches for motor, stirrer, heater and indicator lamps are fixed at a convenient place on the water bath. Complete with three briquette moulds and one base plate, All supply single phase.

Note: Refrigerated ductility testing machine to operate at 27 °C with control accuracy of ± 0.1 °C also available. Price on request. The Ductility Testing Machine can be supplied with Digital Temp. controller for accurate temp. control at extra cost