Semi Automatic Compression Testing Machine | Manual Pace Rate | Printer VSLIC-452SA

short info

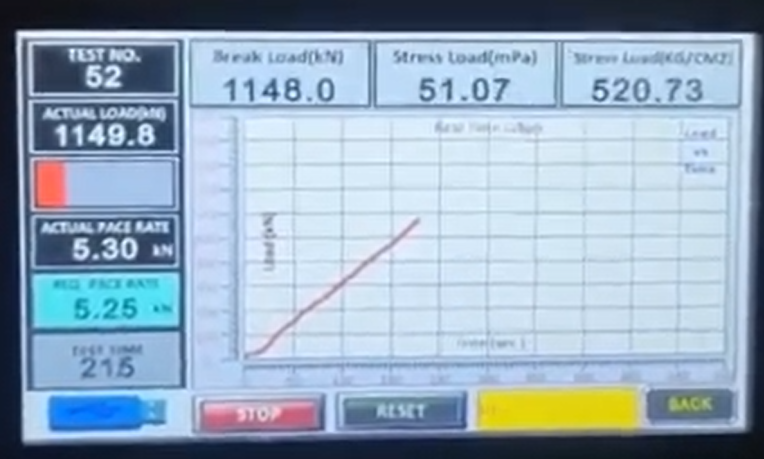

The VERTEX Semi Automatic Compression Testing Machine- CTM have been manufactured for steady testing of concrete cube and cylinder specimens.

Features.

- 7Inch Full HD Touch Screen or HMI.

- Plate Type With Attached Control Panel high stiffness and high stability fully welded construction of the load frame.

- Results Peak Load(kN) + Stress (N/mm2) + Stress (Kg/cm2)

- Can manually control pace rate from 1 KN/Sec to 40 KN/sec.

- Pace rate indication in KN/Sec.

- Bar Graph indication to control the pace rate

- Built in memory for last 1000 readings

- Automatic internal calibration(without Proving ring)

- Safety cut out for overload and electrical short circuit.

- Safety door on the front side for operator safety.

- Compact Pumping unit with manually variable rate of loading.

Standard

Model

Origin

Make/ OEM

Brochure