The Proceq Silver Schmidt OS8200 is the world’s leading digital concrete test hammer, developed by Proceq Switzerland (Screening Eagle Technologies). It redefines non-destructive concrete strength testing (NDT) through digital precision, cloud data connectivity, and universal standards compliance.

Engineered for laboratories, field engineers, and construction professionals, the OS8200 delivers reliable rebound values, accurate compressive strength estimation, and instant digital data recording.

Used in over 100 countries, this smart concrete test hammer is trusted by research institutes, construction companies, and calibration laboratories worldwide.

⚙️ Key Features of Proceq Silver Schmidt OS8200

-

📊 Digital Precision Measurement – Instant rebound value (Q-value) with ±0.5% repeatability.

-

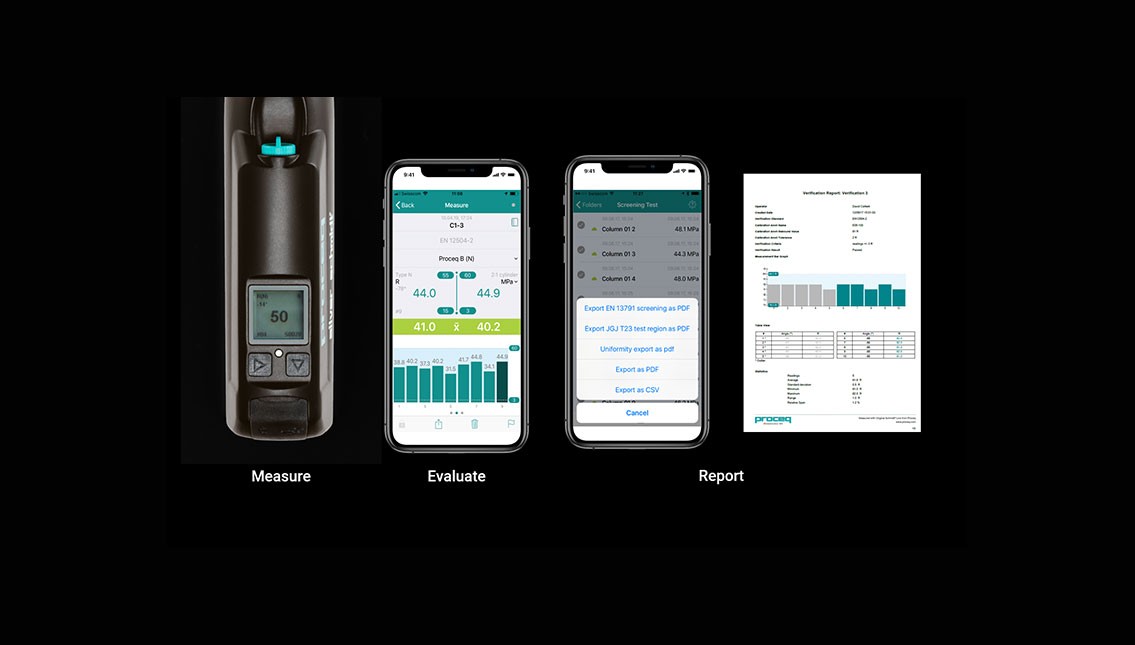

🔗 Smart Connectivity – Bluetooth and USB interface with Proceq Live app for wireless data transfer.

-

💡 Intuitive OLED Display – Clear readings under all lighting conditions with multilingual menus.

-

📱 Cloud Integration – Auto synchronization and live reporting via Screening Eagle Live platform.

-

🧱 Versatile Testing Angles – Automatic correction for horizontal, vertical, and overhead impacts.

-

🌐 Global Standard Compliance – Meets ASTM C805, EN 12504-2, IS 13311 (Part 2), BS 1881, JIS A 1155, and more.

-

🔋 Rechargeable Power System – Long-life Li-ion battery for uninterrupted field testing.

-

🧰 Rugged, Lightweight Design – Compact aluminum body for durability in harsh environments.

📐 Technical Specifications

| Parameter |

Specification |

| Impact Energy |

2.207 Nm (Type N equivalent) |

| Measurement Range |

10 – 100 N/mm² |

| Display |

OLED digital screen |

| Connectivity |

Bluetooth / USB |

| Power Supply |

Rechargeable lithium-ion battery |

| Data Storage |

Cloud & local memory |

| Weight |

Approx. 1.1 kg |

| Standards |

ASTM C805, EN 12504-2, IS 13311 (Part 2), BS 1881 |

🧪 Applications

-

Concrete compressive strength estimation on site and in laboratory.

-

Structural assessment of bridges, tunnels, buildings, and pavements.

-

Quality assurance in precast concrete production.

-

Comparative testing and calibration studies.

-

Periodic inspection of old concrete structures worldwide.

✅ Advantages

-

100% non-destructive testing (no damage to concrete).

-

Digital accuracy superior to manual Schmidt hammers.

-

Fast data capture and automatic report generation.

-

Cloud-based documentation for audits and compliance.

-

Global compatibility with Android, iOS, and PC systems.

🏗️ Why Choose the Proceq Silver Schmidt OS8200

This concrete test hammer is not just an upgrade — it’s a complete digital transformation of rebound testing.

Built on Swiss precision engineering, the OS8200 ensures consistent, traceable, and certified test results that meet the toughest international standards.

-

🌍 Recognized worldwide for accuracy and reliability.

-

🧾 Seamless calibration management through Proceq Live.

-

🔧 Maintenance-free design with minimal recalibration needs.

-

📦 Compact and ready-to-use kit with impact plunger, battery, and carrying case.

🏢 About Vertex Scientific & Lab Instruments

Founded in 2017 by Dr. Anshul Johri, Vertex Scientific & Lab Instruments Company is India’s trusted name in material testing, civil engineering, and NDT equipment.

We provide Proceq instruments, calibration services, and after-sales support to clients across India, Middle East, Africa, and South-East Asia.

-

🔬 ISO-certified calibration laboratory

-

🚚 Pan-India & international delivery

-

🛠️ Professional installation and training

-

📞 24×7 customer support

💬 Order & Enquiry

For best pricing, calibration, and demo:

📞 Vertex Scientific & Lab Instruments Co.

📍 Delhi, India

🌐 www.vertexinstruments.com

✉️ info@vertexinstruments.com | 📱 +91-9999573785

Primary Keywords:

Proceq Silver Schmidt OS8200, Proceq OS8200, Digital Concrete Test Hammer, Concrete Rebound Hammer, Concrete Strength Tester

Secondary Keywords:

Proceq Schmidt Hammer Price, Proceq Rebound Hammer Digital, Concrete NDT Equipment, Concrete Hardness Tester, Proceq Testing Instruments

Long-Tail Keywords:

-

Buy Proceq Silver Schmidt OS8200 online

-

Proceq digital concrete test hammer supplier

-

Best rebound hammer for concrete testing

-

Schmidt hammer calibration service worldwide

-

Proceq OS8200 dealer in India / USA / UAE / UK

Concrete inspection device, Proceq live cloud app, non-destructive concrete strength testing, screening eagle technologies, rebound hammer test IS 13311