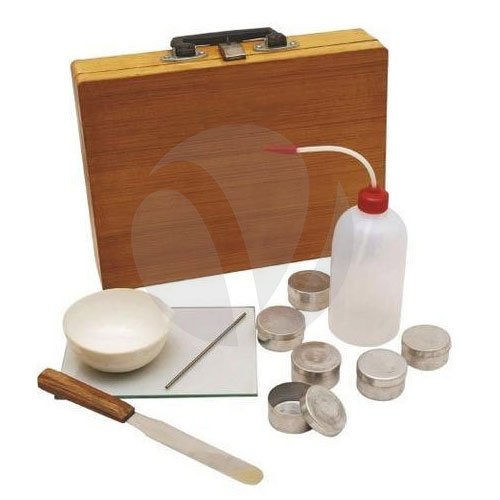

Plastic Limit Test Apparatus

Working Principle (Step by Step)

1. Objective

The Plastic Limit Test apparatus is used to determine the plastic limit (PL) of soil, which is the minimum moisture content at which soil just begins to behave plastically.

2. Sample Preparation

3. Rolling of Soil Thread

4. Reduction in Diameter

5. Crumbling Stage

-

At a particular moisture content, the soil thread starts crumbling or breaking at 3 mm diameter.

-

This condition indicates the soil has reached its plastic limit.

6. Moisture Content Determination

7. Repetition & Average

Working Principle (In One Line)

The plastic limit is the moisture content at which soil changes from a plastic to a semi-solid state, identified by crumbling of soil threads at 3 mm diameter.

Standards Followed

-

IS: 2720 (Part 5)

-

ASTM D4318

Key Advantages

Hindi Version

प्लास्टिक लिमिट टेस्ट उपकरण

कार्य सिद्धांत (स्टेप बाय स्टेप)

1. उद्देश्य

प्लास्टिक लिमिट टेस्ट का उपयोग मिट्टी की प्लास्टिक लिमिट (PL) ज्ञात करने के लिए किया जाता है।

प्लास्टिक लिमिट वह न्यूनतम नमी प्रतिशत है जिस पर मिट्टी प्लास्टिक अवस्था से अर्ध-ठोस अवस्था में बदलने लगती है।

2. नमूना तैयारी

3. मिट्टी की डोरी (Thread) बनाना

4. व्यास कम करना

5. टूटने की अवस्था

-

एक विशेष नमी पर पहुँचने पर, 3 मिमी व्यास पर मिट्टी की डोरी टूटने या बिखरने लगती है।

-

यही अवस्था मिट्टी की प्लास्टिक लिमिट को दर्शाती है।

6. नमी प्रतिशत ज्ञात करना

7. परीक्षण की पुनरावृत्ति

एक पंक्ति में कार्य सिद्धांत

प्लास्टिक लिमिट वह नमी प्रतिशत है जिस पर 3 मिमी व्यास की मिट्टी की डोरी रोल करने पर टूटने लगती है।

मानक (Standards)

-

IS: 2720 (Part-5)

-

ASTM D4318