Features

- Loading accuracy as high as ± 1

- Straining at variable speeds to suit a wide range of materials.

- Printer & PC graphs enable study the behavior of the material.

- Motor driven threaded columns for quick effortless adjustment of lower cross-head-to facilitate rapid fixing of test specimen.

- Simplicity in reading because of digital readouts.

- Wide range of standard and special accessories, including load stabilizer

- Easy change from plain to threaded and screwed specimens.

- Large effective clearance between columns enables testing of standards specimens as well as structures.

- Simple controls for ease of operation.

- Robust straining frame of an extremely rigid construction.

- Safe operation ensured by means of safety devices.

- Fully enclosed and protected pressure transducer.

- RS 232 serial port to transfer data to computer for analysis/storage evaluation etc.

- Manual control & release valve operation.

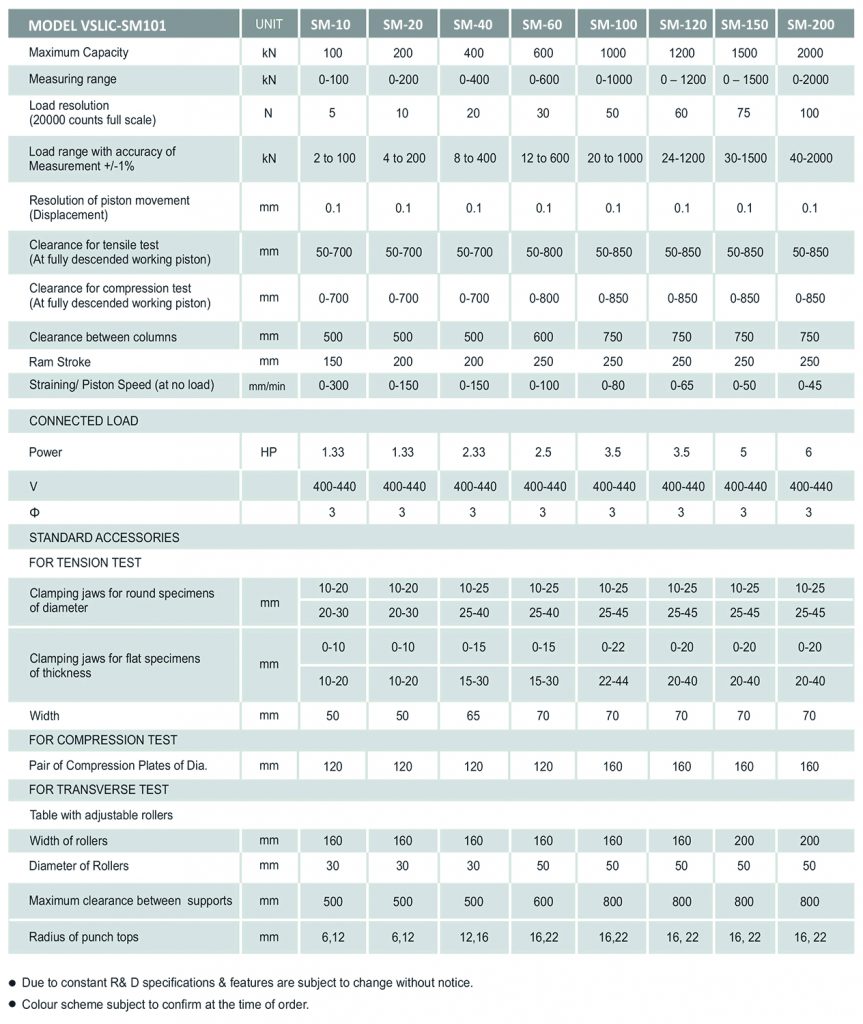

- Load Capacity : 100 kN, 200 kN, 400 kN, 600 kN,1000 kN, 1200 kN, 1500 kN, and 2000 kN.

Microprocessor based panel incorporating state of art technology with following features –

- Front panel membrane type key board for machine operation with numeric keys for data entry.

- 7 segment display.

- Data entry with numeric key board of test parameters including speeds, rupture % peak, pre-load, modulus data, test data & specimen data etc.

- 20 input data set storage, 50 result storage, maintains data and results during power off.

Material Specification

| Automation grade |

Automatic |

| Material |

Mild Steel |

Dimension

| Length of the machine |

2032 millimeter |

| Weight(Aprox) |

1500 kilogram |

| Height of the machine |

1960 millimeter |

| Width of the machine |

750 millimeter |

Specifications

| Pair of comperession plates of diameter |

120 millimeter |

| Maximum clearance between support |

500 millimeter |

| Width |

50 millimeter |

| Clearance between columns |

500 gram |

| Current rating |

10 Ampère |

| Diameter of rollers |

30 millimeter |

| Clearance for tensile at fully descended working piston |

700 millimeter |

| Measuring range |

100 kiloNewton |

| Load range with accuracy measurement |

2 kiloNewton |

| Clamping jaws for round Specimens of diameters |

20 millimeter |

| Resolution of piston movement |

0.1 millimeter |

| Clamping jaws for flat Specimens of thickness |

10 millimeter |

| Ram Stroke |

150 millimeter |

| Machine power |

5 kiloWatt |

| Radius of punch tops |

6 millimeter |

| Voltage |

440 Volt |

| Table width adjustable rollers. width of rollers |

160 millimeter |

| Maximum capacity |

100 kiloNewton |

| Features |

Corrosion resistance,Sturdy construction,noise free,Longer service life,Durable performance |

| Straining/piston speeds (mm/min) |

300 |

| Clearance for Compression test at fully descended working piston |

700 millimeter |

| Load resolution |

10 kiloNewton |