The Fully Automatic Blaine Air Permeability Apparatus is an advanced laboratory instrument designed to determine the fineness of cement and similar powders, expressed as specific surface area (cm²/g). It automates the traditional Blaine method using sensors, digital timers, and software control to ensure precise, repeatable, and user-independent results.

“Fully Automatic Air Permeability apparatus (Blaine type)

Key Components:

-

Permeability Cell:

-

A precision-machined metal cylinder where the cement sample is packed.

-

Designed to maintain a standard porosity.

-

Comes with a perforated disc and filter paper at the bottom and top.

-

Automatic Vacuum/Air Flow System:

-

Digital Manometer or Pressure Sensors:

-

Microprocessor/PLC Control Unit:

-

Controls the timing, measurements, and data processing.

-

Starts/stops the air flow and calculates specific surface area automatically.

-

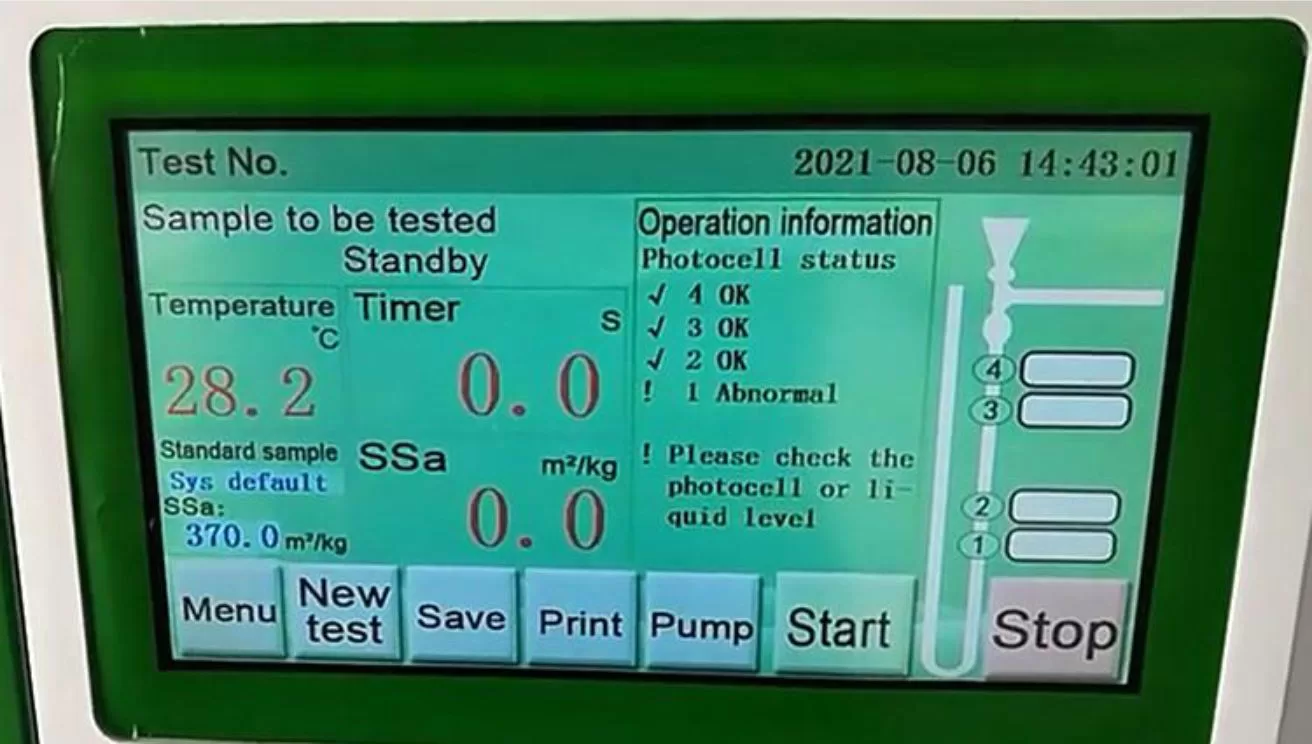

Touchscreen Display or PC Interface:

-

Allows the user to input parameters, start tests, and view results.

-

Some models come with software for data logging and report generation.

-

Temperature Sensor (optional):

Features:

-

Automatic test cycle (filling, timing, calculation, and result display)

-

High accuracy and repeatability

-

User-friendly interface (touchscreen or computer-based software)

-

Built-in calibration and standard test mode

-

Memory for storing multiple test results

-

Compact and low-maintenance design

Measurement Principle:

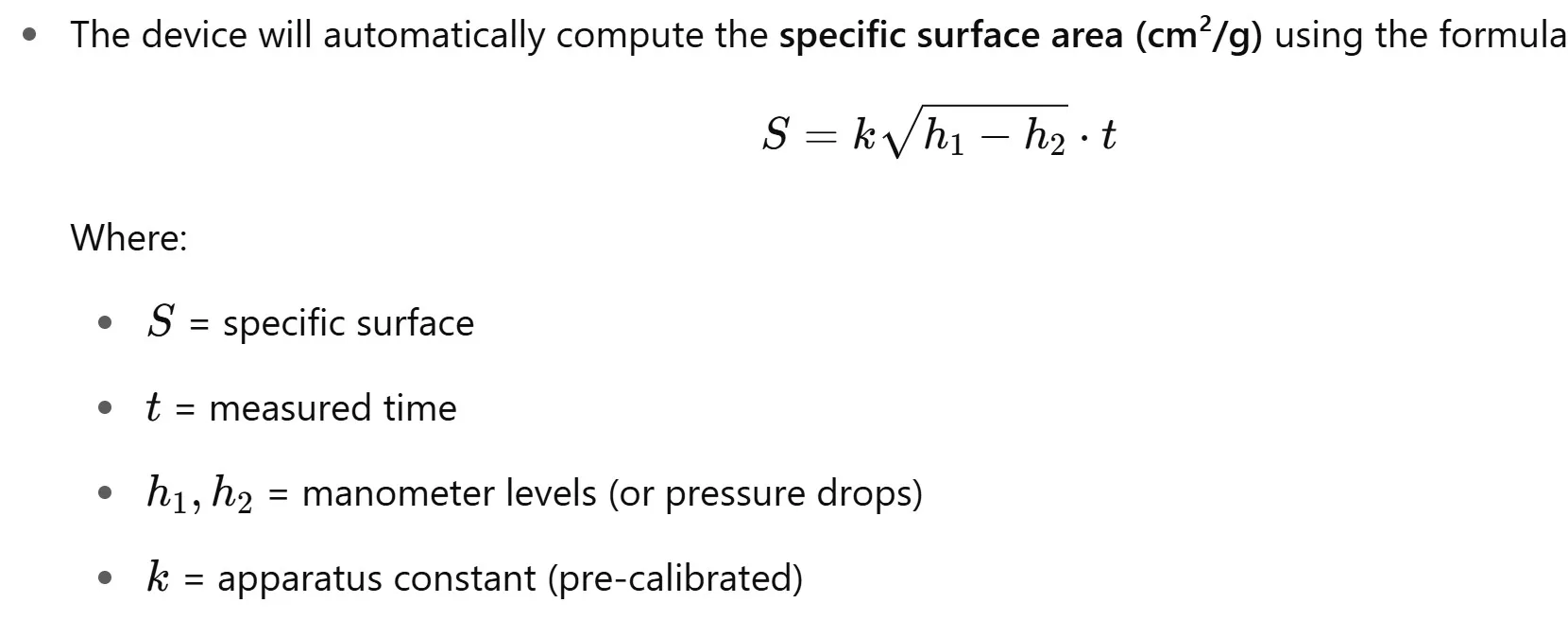

The apparatus determines how long it takes for a known volume of air to flow through a compacted cement bed. The flow resistance is related to the surface area of the particles: finer particles create more resistance. The system uses this time and pressure data to compute the specific surface area (Blaine value).

Applications:

Variable Flow Type Fully Automatic Blaine Air Permeability (Blaine Type): It is used for determination of fineness of cements, pozzolanas and other powdery materials in terms of specific surface, which is expressed as total surface area in square centimetres per gram of the material under test.

Apparatus Details:

The apparatus comprises following parts and accessories

- Standard permeability cell made of brass, 12.5 mm inside diameter with one perforated metal disc and one plunger

- A U-Tube glass manometer with rubber coupling for permeability cell, mounted on a wooden stand.

- Latex rubber tubing, 20 cm long

- 12 Nos filter paper discs, No. 40 whatman

- 200 ml Dibutylphthalate liquid

- Non perforated disc

- Suction Bulb

- Rubber coupling

Characteristic:

- The testing procedure is simple and quick.

- The calculation accuracy of the test results is high.

- 800*480mm color touch screen display.

- The data export function is available.

- The test data is printed in real time, and the historical data is printed again.