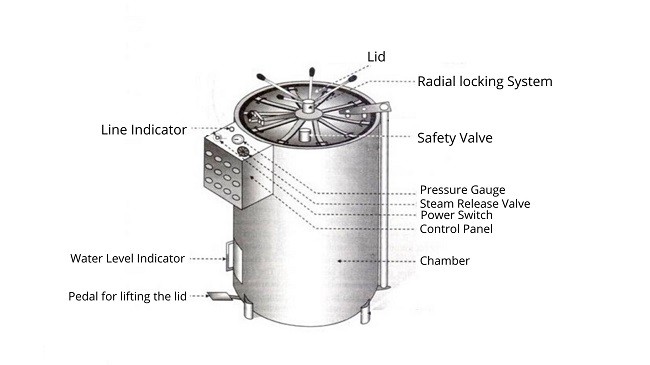

Vertical autoclaves are also known as steam sterilizers. Their primary function is to generate steam, create pressure and build up heat to sterilize medical tools, flasks, beakers and all other medical and research items which needs to be free from bacteria, viruses and all forms of organics.

Vertex is a vertical autoclave manufacturer from New Delhi, India. We are a 2 decade old company and we bring to you a wide range of vertical autoclaves. Our standard range includes a 22 ltr, 35 ltr, 70 ltr, 111ltr and 152 ltr options. These units are extensively used in hospitals and biotechnology laboratories. A vertical autoclave is manufactured in three different designs Economy model, Deluxe Model and Triple Walled. The difference between these models explained below:

Economy Model: In this economy vertical autoclave external surface is made of painted mild steel sheet and inner chamber is made of stainless steel. The lid is made of painted MS but inner part is made of stainless steel sheet. Pressure is controlled through automatic pressure switch.

Deluxe model: In Deluxe vertical autoclave, both inner chamber and external chamber are made of stainless steel and lid is also made of stainless steel. Radial locking system, ring and stand are made of chrome plate MS.

Triple Walled: Triple walled vertical autoclaves are highly effective sterilization equipment and considered most suitable for most of applications. These vertical autoclaves are made with three walls and all walls are made of stainless steel; while radial locking system, ring and stand are made from chrome plated MS. It has steam stock option, where steam is first generated in jacket and then transferred into sterilization chamber.

NOTE: We also undertake custom projects where we manufacture Vertical Autoclaves with custom specifications and dimensions.

Check out the technical specifications of Vertical Autoclaves manufactured by Vertex Scientific & Lab Instruments Co.

VERTICAL AUTOCLAVE: TECHNICAL SPECIFICATIONS

|

| Capacity |

35 Ltrs |

98 Ltrs |

152 Ltrs |

| Chamber Dimension |

300 x 500mm |

450 x 600mm |

550 x 750mm |

| Construction |

SS 304 |

SS 304 |

SS 304 |

| Power Consumption |

2 Kw |

6 Kw |

6 Kw |

| Operating Pressure |

1.2 – 2.1 kg / cm2 |

1.2 – 2.1 kg / cm2 |

1.2 – 2.1 kg / cm2 |

| Operating Temperature |

121째C |

121째C |

121째C |

| Voltage |

220V AC |

220V AC |

220V AC |

| Optional Accessories |

- PLC + HMI controller

- Digital temperature cum timer

- RS232 printer connection

- GMP construction

- Dressing drums

- Extra gasket

|