Automatic Compressıon Testıng Machines are manufactured for compression testing of cubes and cylinders by taking into account user requests for general purposes. This machine designed for compressive-strength testing of larger size specimens.

The machines allow inexperienced operators to perform the test. Once the machine has been switched on and the specimen is positioned and centered by the help of concentric centering line/s of lower bearing block the only required operations are;

- Setting test parameters, including pace rate (only required when the specimen type is changed).

- Pressing the START button on the control unit.

- The machine automatically starts the rapid approach, when the specimen touches the upper platen the rapid approach is ended and starts loading at the pace rate that selected by user and stops once the specimen fails.

- Automatically saves the test parameters and test results.

Pedestal that is made of steel to facilitate the user’s placement of specimens in the frames for compression test should be ordered separately.

The Machines consist of a welded steel frame ( see table), hydraulic power pack with Delta-Touch PRO Control Unit.

Main Features

- Pace Rate control between 0.5 kN to 25 kN

- Load Accuracy Class 1 acc. to EN 12390-4 and acc. to E74 starting from with the 5% of the machine capacity (Special calibration option starting from 1% of the full range.

- Tests automatically with closed loop control

- The tests can be performed by controlling the machine either on Delta-Touch PRO control unit or on a computer with using free VERTEX Software which is provided free of charge with the machines.

- Load measurement with a pressure transducer

- Hydraulic pump with dual stage for rapid approach

- Welded steel walled frame with a single acting piston

- Piston return at the end of test automatically

Safety Features

- Maximum pressure valves to avoid machine overloading

- Limit switch for piston stroke

- Emergency stop button

- Removable transparent front and rear safety doors

- Software controlled maximum load value

- The front safety doors have an automatic safety device to stop the machine if the door is opened during a test.

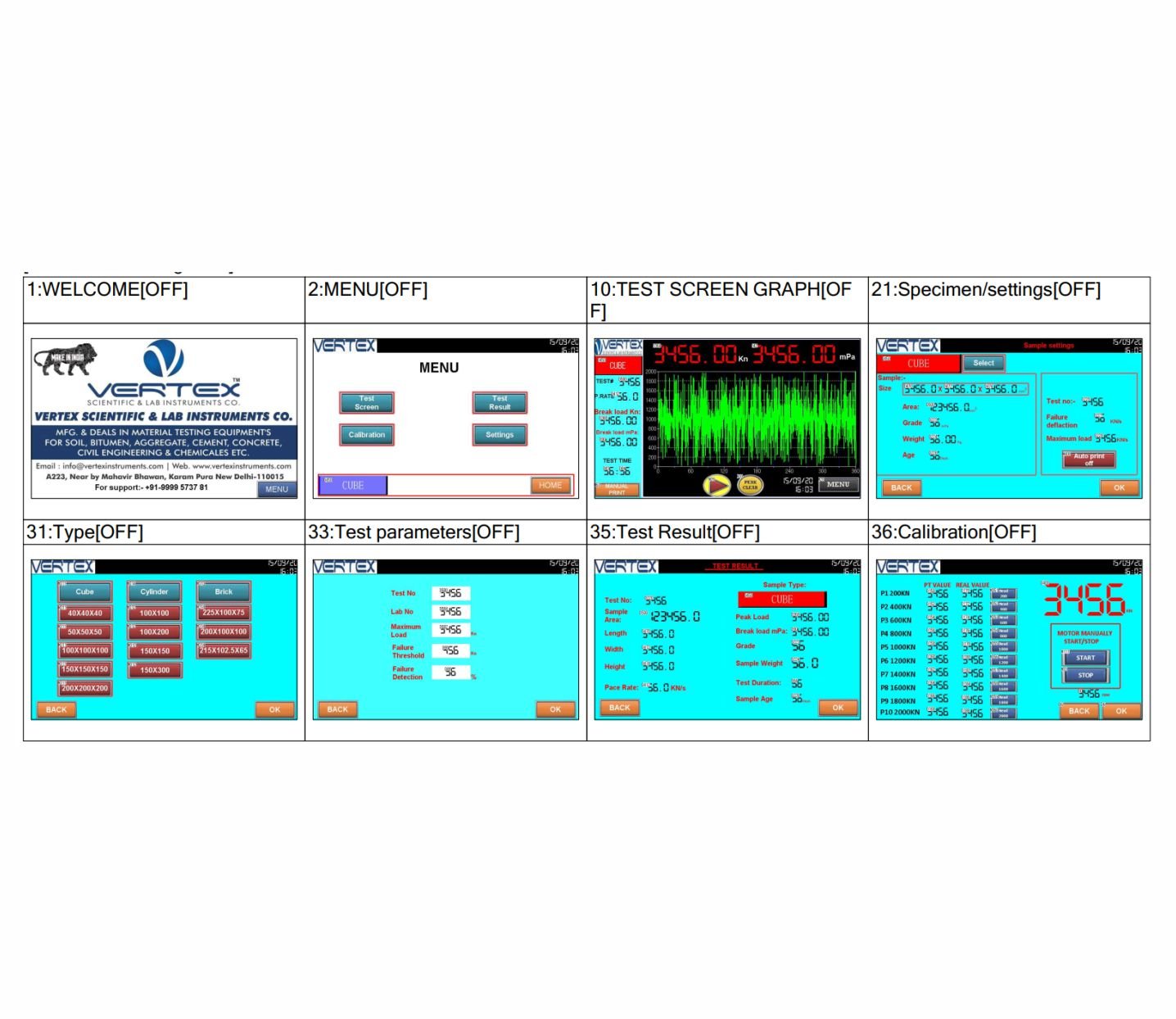

Delta-Touch PRO Control Unit

Delta-Touch PRO Control Unit is designed to perform automatically compression, flexure and splitting tensile strength tests of construction materials such as concrete, cement mortar, masonry units/blocks by controlling the Vertex automatic compression / flexure testing machines.

All the operations of Delta-Touch PRO are controlled from the front panel touch screen display.

U-Touch PRO Control Unit has easy to use menu options. It displays all menu option listings simultaneously, allowing the operator to access the required option in a seamless manner to activate the option or enter a numeric value to set the test parameters. Digital graphic display is able to draw real-time “Load vs. Time”, or “Stress vs. Time” graphics

Vertex Software for Automatic Compression / Flexure Testing Machines

VERTEX software provides to perform automatically compression, flexure and splitting tensile strength tests of construction materials such as concrete, cement mortar, masonry units/blocks by controlling the Vertex automatic compression / flexure testing machines.

The advantages of performing tests on computer with using Vertex Software, such as reporting, graphical output, etc. can be seen in detail at (The VERTEX Software for Automatic Compression / Flexure Testing Machines with Hydraulic Power Pack) pages.

Optional Additional Frame

For compression and especially flexural testing, additionally second testing frame should be ordered separately.

In this case, the machines provide load control of two separate testing frames with closed-loop P.I.D control with automatic test procedure by using selecting test channel And additional selector valve.